Mastering Fiber Optic Cable Installation in AV Systems

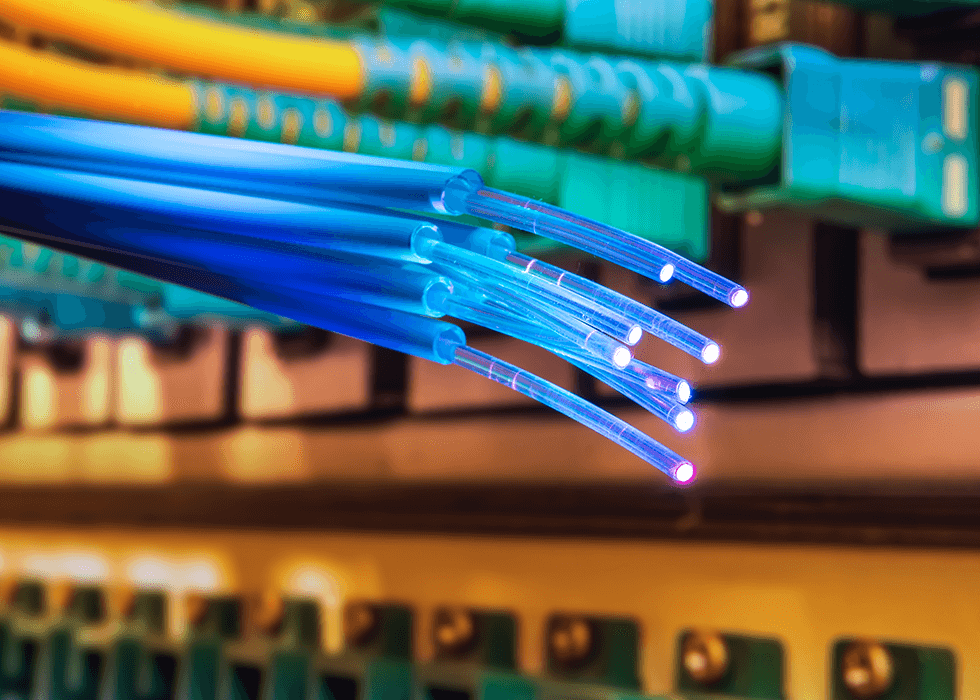

Fiber optic technology has shaken up the audiovisual industry, offering unprecedented bandwidth, signal clarity, and reliability for modern AV installations. As digital content demands continue to grow and systems become more complex, fiber optic cables are standing out as the backbone of professional AV infrastructure, enabling seamless transmission of high-definition video, crystal-clear audio, and control signals across never-before-seen distances without degradation.

The importance of professional installation cannot be overstated when it comes to fiber optic systems. Unlike traditional copper cables, installing fiber optics requires specialized knowledge, precise handling techniques, and specific tools to achieve optimal performance. A properly installed fiber optic network installation ensures maximum system reliability, eliminates signal interference, and provides the foundation for scalable AV solutions that can adapt to future technological advances.

Basics of Fiber Optic Cables

Fiber optic cables consist of several key components that work together to transmit data via light signals. At the core lies the optical fiber itself—an ultra-thin strand of glass or plastic that carries light pulses of digital information. This core is surrounded by a layer with a lower refractive index that keeps light signals confined within the core through total internal reflection. A protective buffer coating shields the fragile fiber from moisture and physical damage, while strength members provide tensile support during installation. Finally, an outer jacket protects the entire assembly from environmental hazards.

The functionality of fiber optic cables relies on the principle of total internal reflection. When light enters the fiber core at the proper angle, it bounces off the core-cladding boundary and travels along the fiber's length with minimal loss. This process allows data to travel at nearly the speed of light across considerable distances while maintaining signal integrity.

In AV applications, we generally see two primary types of fiber optic cables that serve different purposes. Single-mode fiber features a small core diameter (typically 9 microns) that allows only one light path, making it ideal for long-distance transmission with minimal signal loss. These cables excel in applications requiring transmission over several kilometers, such as connecting remote venues or distributing signals across large campuses.

Multi-mode fiber has a larger core diameter (50 or 62.5 microns) that supports multiple light paths simultaneously. While limited in distance compared to single-mode fiber, multi-mode cables offer cost-effective solutions for shorter runs within buildings, and are commonly used in local area networks, equipment racks, and room-to-room connections.

Want to learn more but prefer a live webinar? You’re in luck! Check out our Enterprise IT Power Hour: Fiber Optic Installation happening on September 3.

Register Now

Benefits of Fiber Optic Cables in AV Installations

The primary advantage of fiber optic cable installation is its exceptional bandwidth capabilities. Fiber optic cables can support data rates exceeding 100 Gbps, easily accommodating multiple 4K and 8K video streams, high-resolution audio channels, and control data simultaneously. This bandwidth capacity not only exceeds traditional copper cables but also provides headroom for future system expansions and technology upgrades.

Fiber optic cables have a remarkable immunity to electromagnetic interference (EMI) and radio frequency interference (RFI), whereas these are common problems for copper-based systems. This interference resistance proves particularly valuable in environments with heavy electrical equipment, wireless devices, or industrial machinery. The result is cleaner signal transmission with minimal noise, ensuring consistent audio and video quality throughout the system.

The longevity and durability of fiber optic installations make them ideal for complex AV setups. Properly installed fiber optic cables can operate reliably for decades with minimal maintenance. They resist corrosion, moisture damage, and temperature fluctuations better than copper alternatives. Additionally, fiber optic cables are lighter and more flexible than equivalent copper cables. This simplifies installation in tight spaces and reduces structural load requirements.

Preparing for Fiber Optic Installation

Successful fiber optic installation begins with assembling the proper tools and equipment. Essential tools include fiber optic strippers for removing cable jackets and buffer coatings, precision cleavers for creating smooth fiber end faces, and fusion splicers (or mechanical splice tools) for joining fibers. Connector installation requires specialized crimping tools, polishing equipment, and connector assemblies appropriate for the specific fiber type and application.

Additional equipment includes optical power meters for measuring signal strength, optical time-domain reflectometers (OTDRs) for testing cable integrity, and visual fault locators for identifying breaks or bends in the fiber. Proper safety equipment, including safety glasses and fiber disposal containers, ensures safe handling of glass fibers and prevents contamination.

It is also critical to ensure the site has been prepared adequately. Begin by conducting a thorough survey of the installation route – identifying potential obstacles, bend radius limitations, and environmental hazards. Make sure that conduits, cable trays, and pathways can accommodate the fiber optic cables without exceeding minimum bend radius specifications.

Understanding cable specifications is crucial for compatibility and performance. Verify that the chosen fiber type matches the system requirements, including wavelength compatibility, bandwidth needs, and distance limitations. Check that connectors and adapters are compatible with existing equipment and follow industry standards. It’s also useful to review manufacturer specifications for installation parameters such as pulling tension limits, bend radius requirements, and environmental operating conditions.

Step-by-Step Fiber Optic Installation Process

A successful fiber optic installation depends on careful planning, precise execution, and thorough attention to detail. Following these steps ensures optimal performance, minimal signal loss, and long-term reliability.

- Plan the cable route: Planning the cable route requires careful consideration of physical constraints and performance requirements. Map out the most direct path while avoiding sharp bends, potential interference sources, and areas prone to physical damage. Consider future access needs for maintenance and expansion when selecting routes through walls, ceilings, and equipment rooms.

- Prepare the cable: Cable preparation begins with precise cutting using the aforementioned appropriate tools. Remove the outer jacket carefully to avoid damaging internal fibers, then strip the buffer coating to expose the bare fiber. The key to successful fiber preparation lies in maintaining cleanliness throughout the process —even microscopic contamination can significantly impact signal quality.

- Cleave the fiber: Cleaving the fiber creates a smooth, perpendicular end face essential for low-loss connections. Use a precision cleaver to create a clean break at exactly 90 degrees to the fiber axis. Inspect the cleaved end under magnification to ensure it meets quality standards before proceeding with connector installation.

- Install connectors: Connector installation varies depending on the connector type, but generally involves inserting the prepared fiber into the connector ferrule and securing it with epoxy or mechanical crimping. Follow manufacturer instructions precisely, as improper installation can result in high insertion loss and poor long-term reliability. For fusion splicing, align the fiber ends precisely and use the fusion splicer to create a permanent, low-loss joint.

- Polish the connector and end faces: Polishing the connector end faces requires patience and proper technique. Use successively finer polishing films in a figure-eight pattern, maintaining consistent pressure and monitoring progress under magnification. Proper polishing creates a smooth, scratch-free surface that minimizes insertion loss and back reflection.

- Test the signal integrity: Testing for signal integrity involves measuring optical power levels, insertion loss, and return loss at each connection point. Use calibrated test equipment and follow standardized procedures to ensure accurate measurements. Document all test results for future reference and troubleshooting purposes.

Best Practices and Industry Standards

System reliability begins with avoiding these top two pitfalls. First, never exceed the minimum bend radius specified for the fiber type–excessive bending can cause microbends that increase signal loss and reduce cable lifespan. Additionally, be sure to maintain proper pulling tension during installation, using appropriate pulling grips and lubricants to prevent damage to the cable structure.

Industry standards provide essential guidelines for professional fiber optic installations. The Telecommunications Industry Association (TIA) and Electronic Industries Alliance (EIA) standards establish requirements for commercial building cabling systems. These standards cover everything from cable specifications and testing procedures to labeling and documentation requirements.

Following TIA-942 guidelines ensures that data center and equipment room installations meet industry best practices. This includes proper cable management, maintaining separation between power and data cables, and implementing appropriate environmental controls. Adherence to these standards facilitates system maintenance, troubleshooting, and future upgrades.

Maintenance practices significantly extend fiber optic cable lifespan and maintain system performance. Regular visual inspections can identify potential problems before they cause system failures. Keep connector end faces clean using appropriate cleaning methods and materials. Monitor system performance through periodic testing and maintain detailed records of all maintenance activities.

Practical Applications in AV Systems

Fiber optic cables integrate seamlessly into modern audio-visual installations, supporting everything from simple point-to-point connections to complex distributed systems. In digital signage applications, fiber optic cables enable high-resolution content distribution across multiple displays without signal degradation. Even video walls benefit from fiber optic connections as they maintain perfect synchronization between display panels while eliminating ground loops and interference.

Conferencing systems rely heavily on fiber optic infrastructure to support high-definition video, multi-channel audio, and control signals. Fiber optic cables enable remote camera positioning, distributed audio processing, and centralized equipment location while maintaining the signal quality essential for professional presentations and communications.

Theater and entertainment venues utilize fiber optic cable installation for both permanent and temporary setups. Fixed installations might include fiber optic runs between equipment rooms, stage positions, and audience areas. Touring productions benefit from portable fiber optic systems that provide reliable, high-quality connections in various venues—again, without concern for electrical interference or ground loops.

Corporate environments increasingly depend on fiber optic cable installation for boardrooms, training facilities, and collaboration spaces. These installations often integrate with existing network infrastructure and provide both AV signal distribution and data connectivity through a single fiber optic cable plant.

Troubleshooting and Maintenance Tips for Fiber Optic Cables

Common fiber optic issues typically manifest as signal loss, intermittent connections, or complete signal failure. Systematic troubleshooting begins with visual inspection of all connections, looking for contamination, physical damage, or improper mating. Use a visual fault locator to identify breaks, excessive bends, or other physical problems along the cable route.

Optical power measurements can help isolate problems by comparing measured values to system specifications and baseline readings. Any significant deviations from expected values indicate potential issues requiring further investigation. OTDR testing provides detailed information about cable conditions, splice quality, and the location of any faults along the fiber route.

When signal quality issues arise, check connector cleanliness first– contaminated connectors are by far the most common culprit. If needed, clean connectors using appropriate materials and techniques and then retest the system. If problems persist, inspect the connector end faces under magnification for physical damage or poor polish quality.

Regular system maintenance prevents many common problems and extends system lifespan. Establish a schedule for periodic cleaning of all connectors (yes, even those in equipment racks that are rarely disturbed). Monitor system performance through regular testing and maintain detailed records of all measurements and maintenance activities.

Though fiber optic cable installation is generally more durable than its copper counterpart, environmental factors can still impact system performance. Monitor temperature and humidity levels in equipment areas, and ensure that cable installations remain within specified environmental limits. Protect outdoor cable runs from moisture infiltration, temperature cycling, and mechanical stress.

Fiber Optic Cable Installation: The Takeaway

Fiber optic cables represent the gold standard for professional AV installations, offering unmatched bandwidth, signal quality, and reliability. Upgrading to a fiber optic cable installation offers benefits such as reduced interference, exceptional longevity, and future-proof performance, making fiber optic networks an essential component of modern audiovisual infrastructure.

While the initial investment in fiber optic technology may be higher than that of traditional copper systems, the long-term advantages in performance, reliability, and maintenance costs provide compelling value for professional installations.

Achieving these advantages depends on careful planning, precise execution, and adherence to industry standards. Following proper installation techniques, maintaining clean working conditions, and conducting regular maintenance ensure that fiber optic systems continue to deliver exceptional performance throughout their lifespan.

As AV technology continues to advance, systems will demand ever-higher bandwidth, longer transmission distances, and greater reliability—capabilities that fiber optic cables are designed to deliver, ensuring both current performance and future readiness.

To take your skills to the next level, consider signing up for AVIXA’s Enterprise IT Power Hour: Fiber Optic Installation class, where you can gain hands-on knowledge and practical insights from industry experts.

Photo credit: Getty Images/kynny