Chip on Board LED: Benefits and Applications in Professional AV Solutions

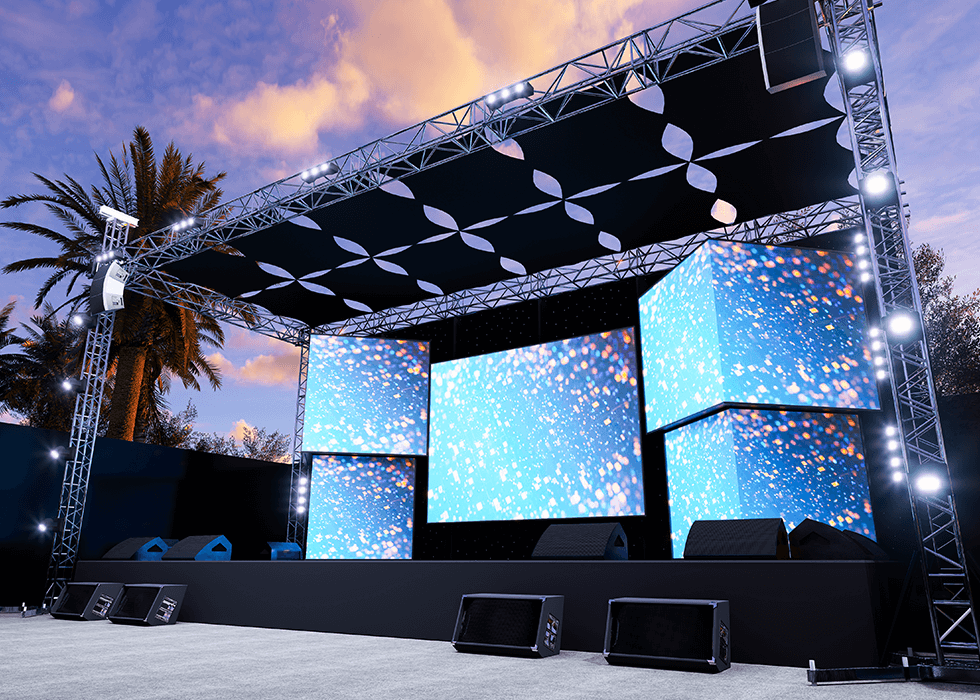

LED (Light Emitting Diode) technology has transformed the professional AV industry over the past two decades. From large-scale video walls to precision lighting in live events and studio environments, LEDs have become the go-to light source due to their energy efficiency, vibrant colors, compact design, and flexibility. As AV experiences grow more immersive and high-resolution, the demand for LED innovation continues to rise.

Introduction to Chip on Board (COB) LEDs

Enter Chip on Board (COB) LEDs—a next-generation solution that offers even greater performance and integration potential for pro AV applications. Chip-on-board LEDs represent a significant evolution in LED technology. For the pro AV industry—where image clarity, brightness uniformity, and compact design are paramount—COB LEDs provide a compelling solution. Whether for video production, immersive environments, or performance lighting, COB technology elevates both functionality and design.

Significance of COB LEDs in Modern Displays and Lighting

COB LEDs are redefining how AV professionals think about brightness, resolution, and flexibility. With minimal pixel pitch, seamless modules, and exceptional thermal stability, COB LEDs are powering everything from micro-pitch LED video walls in control rooms to high-lumen projectors and stage lighting. Their ability to deliver consistent performance in demanding environments makes them particularly well-suited to modern AV installations.

What is Chip on Board LED Technology?

Chip on Board (COB) LED technology is a method of LED packaging where multiple tiny LED chips (often hundreds) are directly mounted onto a single substrate or board to form one lighting module. This compact design yields higher light output, enhanced heat dissipation, and a cleaner aesthetic for end products.

Difference Between COB LEDs and Traditional LED Solutions

In traditional Surface Mount Device (SMD) technology, individual LED chips are soldered separately onto a Printed Circuit Board (PCB), which can lead to uneven brightness and visible gaps in high-resolution displays. By contrast, COB LEDs use a single circuit with multiple chips bonded directly onto it. This results in:

- Higher packing density of LEDs

- Improved thermal conductivity

- Reduced pixelation and visible gaps

- Streamlined manufacturing process

Composition and Structure of COB LED Modules

A COB LED module typically includes:

- LED chips: Small diodes arranged densely on the substrate.

- Substrate: Often made of ceramic or aluminum for thermal conductivity.

- Encapsulation layer: A phosphor-coated resin or silicone dome for light diffusion and protection.

- Thermal management system: Heat sinks or integrated systems to dissipate excess heat.

The entire module is then mounted on an appropriate board or housing, depending on the application.

Key Advantages of Chip-on-Board LEDs

Enhanced Brightness and Uniformity

Since the LED chips are closely packed and emit light from a single surface, COB LEDs deliver high-lumen output with minimal shadowing. This is particularly advantageous for pro AV displays where brightness, uniformity, and accurate color rendering are critical. In applications such as broadcast studios or trade show displays, brightness consistency is critical to creating a polished, professional look. The absence of dark lines or uneven lighting with COB LEDs enhances visual clarity and boosts audience engagement.

Superior Thermal Management

Heat is a significant threat to the longevity and performance of LEDs. COB LEDs excel in thermal management due to their direct contact with a heat-conductive substrate. This efficient heat dissipation prevents thermal buildup, allowing for stable performance over extended periods, making them ideal for installations such as 24/7 video walls or event lighting rigs.

Compact Design for Seamless Integration

COB technology enables smaller, more integrated modules without compromising output. This compactness is particularly crucial in professional AV, where space-saving designs lead to more elegant and efficient installations. Whether it’s a conference room display or a ceiling-mounted projector, COB LEDs facilitate easier and cleaner integration.

Increased Lifespan and Reliability

Fewer solder points and better thermal properties contribute to a longer operational lifespan. In professional environments—where downtime can be costly—this reliability ensures lower maintenance costs, fewer replacements, and a better return on investment.

Applications of Chip-on-Board LED Technology in the Pro AV Industry

High-Definition Video Walls and Displays

COB LEDs are ideal for fine-pitch video walls used in control rooms, command centers, event venues, and corporate lobbies. Their dense pixel configuration allows for high resolution even at close viewing distances. Seamless visual continuity and high contrast ratios elevate the viewing experience.

Customizable LED Strip Solutions

For scenic and architectural lighting in stage productions, museums, or themed environments, COB LED strips offer smooth, even illumination without hotspots. Unlike SMD strips, which may display individual diode points, COB strips create a continuous light line—perfect for ambient or accent lighting where visual consistency is key.

High-Powered Projectors and Spotlights

Live event lighting demands brightness, accuracy, and thermal stability—traits that COB LEDs excel in. They are commonly used in high-lumen projectors, stage spotlights, and followspots. The compact footprint also allows for lighter and quieter lighting instruments, which is crucial for unobtrusive setups in theaters and live shows.

Integration in Compact AV Installations

From retail displays to museum exhibits, many AV installations require efficient, low-profile lighting and display components. COB LEDs allow integrators to design sleek systems that don’t compromise on brightness or durability, even in tight or unconventional spaces.

Common Misconceptions and Challenges with Chip-on-Board LEDs

Misconception: COB LEDs Are Too Expensive

While COB LEDs may have a higher upfront cost compared to traditional LEDs, they often prove more economical in the long run due to lower maintenance costs, energy savings, and longer life cycles. The total cost of ownership (TCO) favors COB, particularly in 24/7 professional AV applications.

Misconception: COB LEDs Can't Scale for Large Installations

Early versions of COB LEDs struggled with scalability for massive display formats. However, recent advances in manufacturing have enabled the development of modular COB panels that can scale seamlessly across large video walls and broadcast displays, maintaining uniformity and reliability.

Challenge: Heat Dissipation and Reliability

Thermal management was once a limiting factor in COB technology. Today, high-performance substrates and integrated cooling designs have largely mitigated this concern. Leading manufacturers now provide COB modules with advanced thermal architecture to handle continuous professional use.

Factors to Consider When Choosing COB LEDs for Pro AV Projects

Thermal Management Capabilities

Pro AV environments can involve prolonged use, often in enclosed or heat-sensitive areas. Selecting COB modules with high-grade heat sinks, ceramic substrates, or active cooling systems ensures stable performance.

Brightness and Color Consistency

Evaluate the module’s lumens per watt (efficacy) and Color Rendering Index (CRI). In pro AV, especially in broadcast and digital signage, accurate color reproduction is critical. Select COB LEDs with a CRI of 90 or higher for best results.

Durability and IP Ratings

For outdoor or high-exposure environments, COB LED modules should have an IP65 rating to ensure protection against dust and water jets. For more demanding conditions—like heavy rain, coastal areas, or industrial settings—IP66 or IP67 is more appropriate.

Compatibility with Existing Equipment

Ensure COB modules integrate well with your AV control systems, dimming protocols, and housing configurations. Some manufacturers offer pre-calibrated solutions or plug-and-play modules for simplified deployment and setup.

Vendor Reputation and Warranty

Opt for trusted brands with proven track records in professional environments. A solid multi-year warranty of three to five years and local support infrastructure can make a big difference when scaling or servicing an installation.

Chip on Board LED: The Takeaway

As pro AV continues to evolve with more immersive and visually complex experiences, COB LED technology offers a powerful toolkit for integrators, designers, and operators. Its unique combination of high brightness, uniform output, thermal efficiency, and compact form factor makes it a standout option for a wide range of applications, including video walls, stage lighting, digital signage, and architectural visuals.

AV professionals looking to future-proof their installations should consider Chip on Board LED solutions, not just as a lighting upgrade, but as a strategic asset for quality, performance, and longevity.

By integrating COB LEDs into your next AV project, you’re not only investing in cutting-edge technology but also in a more consistent, reliable, and visually stunning experience for your clients and audiences.

Photo credit: Getty Images/Mustapha GUNNOUNI